FEATURES & ADVANTAGES

HC PRECAST SYSTEM

HC precast system comprises of a series of precast wall panels, which are generally designed as load bearing wall system, and interconnected with cast in-situ joints or columns. The in-situ joints are reinforced in accordance to structural requirement and they provide the stability to the building, at the same time eliminate the possibility of ingress of water. These in-situ joints can also act as columns to support heavily loaded beams and allow a hybrid system of conventional and precast structural system to be achieved.

FEATURES

- External wall panels are designed with attractive architectural features

- Size of precast wall panels can be varied in width, as well as height, to suit any architectural or structural design requirements

- Length and size of columns can be adjusted according to architectural and structural requirements

- Precast wall panels allow flexibility of making certain openings, such as windows or doors

- The column moulds are formed with attractive architecture curves and give the wall and column intersection an attractive architrave

- By casting the in-situ columns, the wall and columns form an integral and strong structural member

- Moulds can be delivered to the project site to minimize the transportation costs

ADVANTAGES OF HC PRECAST SYSTEM

The advantages of HC Precast System are as follows :-

- Various sizes of wall panels can be erected and the alignment of precast wall panels can be easily controlled by placing the timber markers for the precast walls to be seated. In this manner, the central line control of the precast wall panels can be achieved

- Any slight out of alignment of the wall panels can be easily concealed with the cast-in-situ columns/joints

- The cast in-situ columns and precast wall panels form an integral and strong structural element

- The cast in-situ columns prevent any possible ingress of water

- The cast in-situ columns and flexibility of the wall panel make this system adaptable to most existing design and hence provide versatility for architects to plan the layout

- The column moulds consist of various combination of the standard modules – hence allowing the flexibility of achieving various column sizes

- The width and height of the precast wall panels can be adjusted

- Minimal touching up is required as there is column and wall joints are formed with smooth formwork system

RANGE OF PRODUCTS

PRECAST WALL PANEL

- The thickness of the precast wall panels can be varied, depending on the structural engineering requirements by changing the height of the side formwork

- The size of wall panels can be adjusted in terms of both height and width to satisfy architectural requirements and functional purpose of the building

- The wall panels are cast in the specially designed mould

- The edge of the precast wall panels is cast with a shear key joint. This shear key, coupled with starter bars, provides very strong interlocking and strength after the columns have been cast

COLUMNS

- Various column or joint shapes are formed as a result of the intersection of the different wall panels. The columns are formed by basically clamping the various wall panels with specially designed moulds

- Standalone columns can also be constructed with the same mould

- The column moulds consist of a series of standard module design of moulds, interlocked and assembled to form various shapes of columns required

- The size of the columns can be easily increased or reduced by increasing or reducing the number modules

- The moulds are made from aluminium to achieve the desired pattern and to make it light to handle

SLAB PANELS

- The slab can be either carried out as in-situ construction of precast planks with concrete topping. It is highly recommended the toilet area to be done as in-situ construction to negate any water leakage problem.

- For precast planks and with concrete topping construction :-

-The precast plank are precast in sleeping moulds

-Starter bars are left at the edges for interconnection of cast in-situ beams and columns

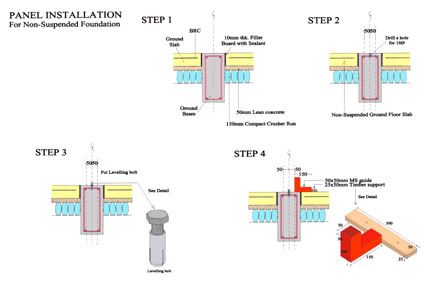

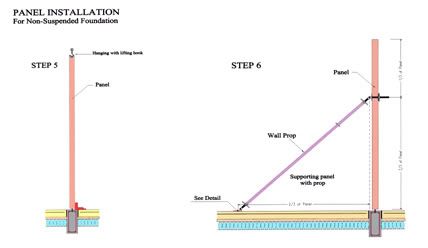

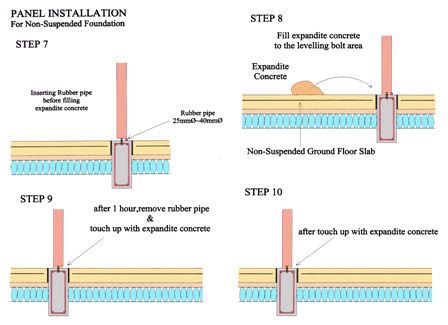

PANEL INSTALLATIONS

SEQUENCE OF CONSTRUCTION & INSTALLATION

The precast wall panels are either cast in the factory or at the site with the specially designed moulds. The ground beams or raft foundations are constructed first.

- Leveling bolts are installed to control the level

- The precast wall panels are erected and supported by 2 no of push pull props

- The vertical alignment of the panels are verified with the level. The verticality can be adjusted with the use of push pull props

- Specially designed aluminium column moulds are erected and clamped against the precast wall panels. Specially designed ties are used to hold the columns against the erected precast wall panels during casting of columns

- Pockets of recess are allowed in the columns for any cast-situ beams or precast beams

REFFERENCES:

http://www.hcprecastsystem.com.my/

No comments:

Post a Comment